Why Your Industrial Processes Need an Inline Static Mixer

What is an Inline Static Mixer?

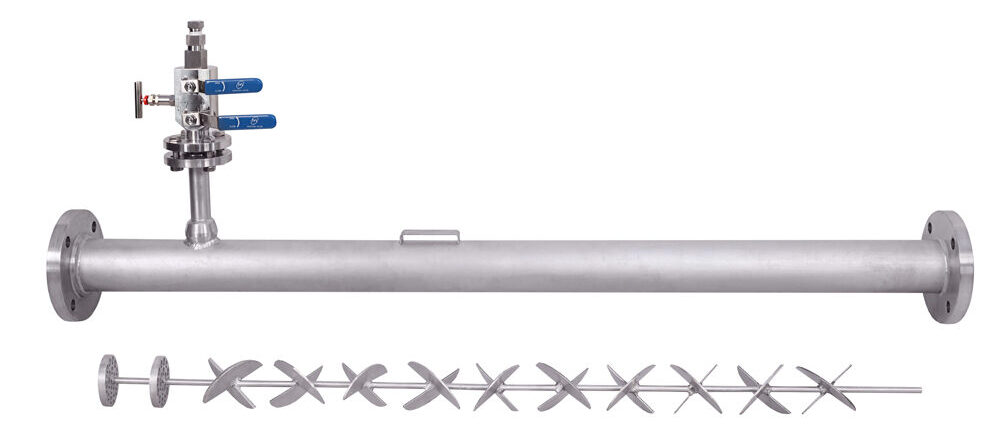

An inline static mixer is a type of mixing equipment used to combine different fluids or gases in a continuous flow process. Unlike dynamic mixers that use moving parts, inline static mixers rely on fixed elements within a pipe to achieve thorough and efficient mixing.

Here’s a quick overview of its components and how it functions:

- 1. Mixer Elements : A series of fixed, geometrically designed components inside a pipe.

- 2. Flow Path : The fluid or gas flows through the mixer, where these elements create turbulence and promote mixing.

- 3. No Moving Parts : Static mixers achieve mixing through fixed, strategically arranged internal components.

How Does an Inline Static Mixer Work?

inline static mixers operate based on the principle of fluid dynamics. As the mixed fluids or gases pass through the mixer, the static elements create multiple layers of flow and eddies. This process disrupts the flow and promotes thorough mixing without the need for external energy sources or mechanical agitation.

Key Principles of Operation:

- 1.Layering : The mixer divides the fluid into layers, which are then recombined in a series of complex patterns.

- 2. Shearing : The design creates shear forces that blend the fluids together.

- 3. Mixing : Through continuous, repetitive processes, the fluids achieve a uniform mixture.

Top 5 Reasons Your Industrial Processes Need an Inline Static Mixer

1. Enhanced Mixing Efficiency

One of the primary advantages of an inline static mixer is its ability to achieve high mixing efficiency. Unlike traditional mixing methods that may require significant energy inputs, static mixers use the natural flow of the fluids to produce a homogeneous mixture.

Benefits:

- Uniform Product Quality :

Ensures consistent product quality across the production line. - Reduced Mixing Time :

Speeds up the mixing process compared to manual or batch methods.

2. Lower Energy Consumption

Inline static mixers are designed to operate without external moving parts, which significantly reduces the energy required for mixing.

Benefits:

- Cost Savings :

Lower energy bills for your operations. - Eco-Friendly :

Reduces the carbon footprint of your manufacturing processes.

3. Minimal Maintenance Requirements

With no moving parts, inline static mixers have fewer components that can wear out or break down.

Benefits:

- Reduced Downtime :

Less frequent maintenance means fewer production interruptions. - Long-Term Reliability :

Durable and reliable for long-term industrial use.

4. Versatile Applications

inline static mixers are highly versatile and can be used in a variety of industrial applications.

Applications :

- Chemical Mixing :

Ideal for combining reactive chemicals. - Food and Beverage :

Used in processes like ingredient mixing and flavor blending. - Pharmaceuticals :

Ensures thorough mixing of ingredients for drug production. - Water Treatment :

Effective in chemical dosing and water purification.

5. Cost-Effective Solution

Compared to other mixing solutions, inline static mixers offer a cost-effective alternative for many industries.

Benefits:

- Lower Initial Investment :

Affordable compared to high-maintenance dynamic mixers. - Operational Efficiency :

Offers a high return on investment through operational savings.

Conclusion

An inline static mixer is a game-changer for industrial processes, offering efficient, cost-effective, and consistent mixing. By integrating an inline static mixer, you can achieve superior product quality, reduce operational costs, and optimize space in your production line. Its low maintenance requirements, energy efficiency, and versatility across various applications make it an essential tool for enhancing process control and boosting overall productivity.

Adopting this technology will lead to improved process efficiency, cost savings, and better product outcomes, making it a smart investment for any modern industrial operation.