Why Venturi Tubes Are Essential for Accurate Flow Measurement in NND Oil & Gas.

Introduction

Accurate flow measurement is crucial in NND Oil & Gas , where precision impacts operational efficiency, product quality, and regulatory compliance. Venturi tubes are renowned for their reliability and accuracy in flow measurement. This blog explores why Venturi tubes are essential for precise flow measurement in NND Oil & Gas and how they can enhance your operations.

1. What Is a Venturi Tube?

Definition and Principle :

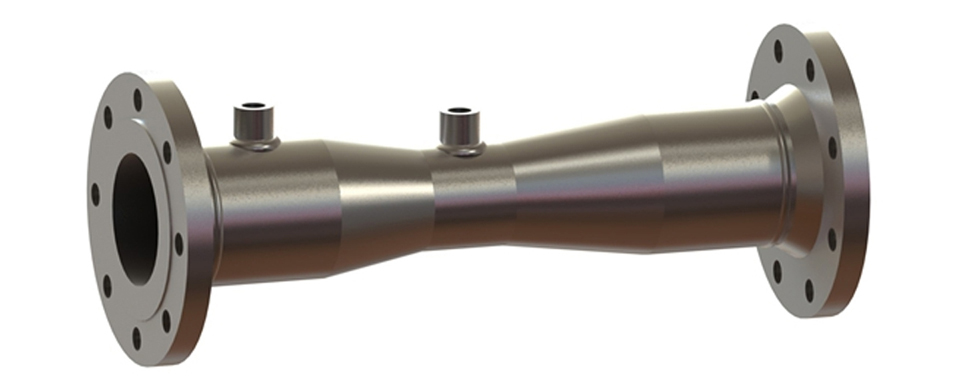

A Venturi tube is a flow measurement device based on the Venturi effect, named after the Italian scientist Giovanni Battista Venturi. It measures fluid flow by creating a pressure differential through a constriction in the flow path. Key components include:

-

1. Converging Section :

The segment where the fluid’s cross-sectional area narrows, increasing velocity and reducing pressure.

-

2. Throat :

The narrowest part of the tube where the fluid velocity is at its peak and pressure is at its lowest.

-

3. Diverging Section :

The section where the cross-sectional area widens, causing the fluid velocity to decrease and pressure to rise.

How It Works :

As fluid flows through the converging section, it speeds up, resulting in a pressure drop. By measuring the pressure difference between the wide and narrow sections, the flow rate can be accurately calculated using Bernoulli’s principle.

2. Why Venturi Tubes Are Essential for Accurate Flow Measurement

High Precision and Accuracy

Venturi tubes are celebrated for their high precision in flow measurement. Their design minimizes flow disturbances and pressure losses, which translates to accurate and stable measurements. In NND Oil & Gas, where precision is vital for maintaining efficiency and product quality, Venturi tubes offer a reliable solution for consistent flow measurement.

Durability and Reliability

Built from robust materials, Venturitubes are engineered to withstand harsh environments, including high pressures, corrosive fluids, and extreme temperatures. This durability ensures reliable performance over time, reducing the frequency of maintenance and replacements in NND Oil & Gas.

No Moving Parts

One of the key advantages of Venturi tubes is their lack of moving parts. This design feature significantly reduces the risk of mechanical failure and wear. It translates to lower maintenance needs and longer operational lifespans, making Venturi tubes a cost-effective choice for continuous flow measurement.

Versatility in Applications

Venturi tubes are highly versatile and can measure a wide range of fluids, including liquids, gases, and slurries. This adaptability is particularly beneficial in NND Oil & Gas, where different processes and fluid types require accurate flow measurement solutions.

Cost-Effectiveness

Venturi tubes offer long-term cost savings due to their low maintenance requirements and high durability. They do not require frequent recalibration or replacement, leading to reduced operational costs and a favorable return on investment.

3. Case Studies and Examples

Chemical Manufacturing :

In a chemical manufacturing facility, Venturi tubes were used to measure the flow of reactive chemicals. Their precise measurements helped optimize chemical reactions and improve product consistency, while their durability handled the corrosive nature of the chemicals effectively.

Oil and Gas Pipeline :

Venturi tubes were implemented in an oil and gas pipeline to measure the flow of crude oil under high pressure. The tubes’ ability to provide accurate measurements in challenging conditions improved pipeline efficiency and reduced maintenance costs.

4. Selecting the Right Venturi Tube

Factors to Consider

When choosing a Venturi tube for your application, consider the following factors:

-

1. Flow Rate Range :

Ensure the tube is suitable for the expected flow rates.

-

2. Fluid Properties :

Select a tube compatible with the characteristics of your fluid, such as viscosity, density, and temperature.

-

3. Installation Requirements :

Assess space and installation constraints to ensure proper fitting and operation.

Expert Advice

Consult with experts or manufacturers to identify the best Venturi tube for your specific needs. They can offer insights into suitable models and configurations based on your application requirements.

5. Future Trends and Innovations

Emerging Technologies

Advancements in Venturi tube technology include improvements in materials, integration with digital sensors, and enhanced accuracy. Smart Venturi tubes with real-time data analytics are expected to further enhance flow measurement capabilities.

Industry Impact

These innovations are likely to drive greater precision and efficiency in NND Oil & Gas, leading to improved operational performance and cost savings.

Conclusion

Venturi tubes are essential for accurate flow measurement in NND Oil & Gas due to their precision, durability, and cost-effectiveness. Their robust design, lack of moving parts, and versatility make them an ideal choice for various applications. By selecting the right Venturi tube for your needs, you can enhance operational efficiency, ensure product quality, and achieve long-term cost savings.