The Science Behind Dosing Pumps: How Do They Ensure Precise Measurement in Industries?

Introduction

In the world of industrial processes, precision and accuracy are paramount. Whether in chemical manufacturing, water treatment, food processing, or pharmaceuticals, the need to measure and dispense liquids and chemicals accurately is crucial. This is where dosing pumps come into play. These sophisticated devices are engineered to ensure that precise amounts of fluids are delivered consistently, maintaining the integrity and efficiency of industrial operations. But how do dosing pumps achieve such remarkable precision? Let’s delve into the science behind dosing pumps and understand their mechanisms.

What Are Dosing Pumps?

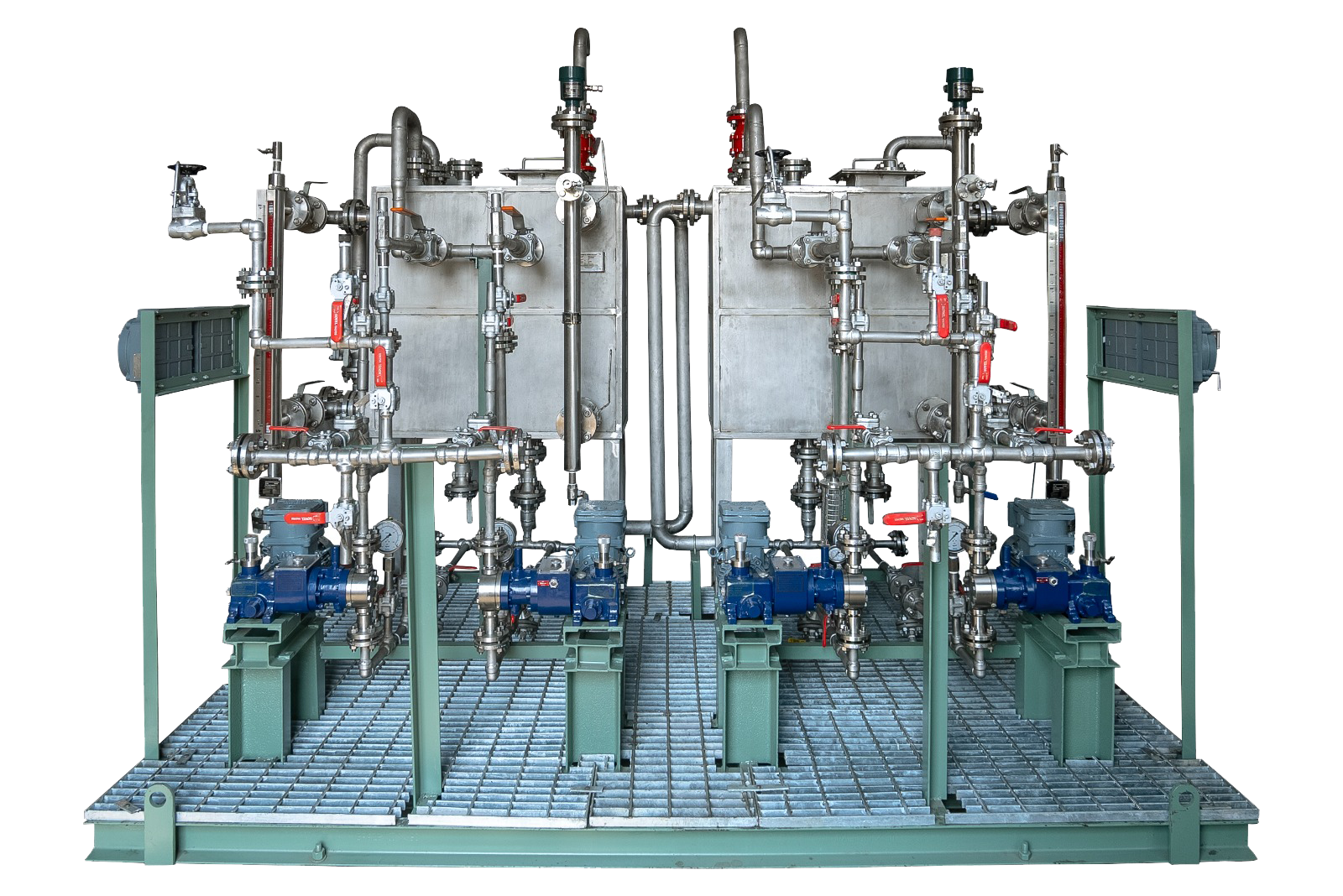

Dosing pumps, also known as metering pumps, are positive displacement pumps designed to inject a precise volume of liquid into a process stream or container. They are equipped with a range of controls to regulate the flow rate and ensure that the exact amount of fluid is dispensed at the required time. Dosing pumps are widely used across various industries, including water treatment, chemical processing, pharmaceuticals, and food and beverage production.

The Working Principle of Dosing Pumps

At the core of dosing pumps is the positive displacement mechanism. This mechanism ensures that a fixed amount of fluid is moved with each cycle of the pump. Here’s a breakdown of how it works:

-

1. Diaphragm and Piston Mechanism:

Most dosing pumps use a diaphragm, piston, or a combination of both to move the fluid. The diaphragm or piston is driven by an electric motor or a solenoid. As the motor or solenoid activates, it moves the diaphragm or piston back and forth, creating a vacuum that draws the fluid into the pump chamber on the intake stroke and expels it on the discharge stroke.

-

2. Check Valves:

To ensure that the fluid flows in only one direction,dosing pumps are equipped with check valves at the inlet and outlet.These valves open and close in response to the pressure changes caused by the movement of the diaphragm or piston, preventing backflow and ensuring precise dosing.

-

3. Flow Control:

Dosing pumps come with adjustable flow control mechanisms. This allows operators to set the desired flow rate, ensuring that the correct amount of fluid is dispensed. Flow control can be manual or automated, depending on the complexity of the system and the specific application.

Ensuring Precision in Dosing

Several factors contribute to the high precision of dosing pumps:

-

1. Accurate Calibration:

Dosing pumps are calibrated to ensure that the volume of fluid dispensed per stroke is consistent. Regular calibration checks and adjustments are necessary to maintain accuracy, especially in applications where even minor deviations can have significant consequences.

-

2. Advanced Control Systems:

Modern dosing pumps often incorporate advanced control systems, including programmable logic controllers (PLCs) and digital interfaces. These systems enable precise control over the dosing process, allowing for real-time adjustments and monitoring. They can also be integrated with other industrial systems for seamless operation.

-

3. Material Compatibility:

The materials used in the construction of dosing pumps are chosen based on the type of fluid being handled.This ensures that the pump components do not react with the fluid,which could compromise accuracy. For example, pumps used in chemical processing are often made from materials resistant to corrosion and chemical attack.

-

4. Temperature and Pressure Compensation:

Changes in temperature and pressure can affect the viscosity and flow rate of fluids. Dosing pumps are designed to compensate for these variations, ensuring consistent dosing regardless of environmental conditions.

Applications of Dosing Pumps

The precision and reliability of dosing pumps make them indispensable in various industries:

-

Water Treatment:

Dosing pumps are used to add precise amounts of chemicals, such as chlorine or coagulants, to water treatment processes. This ensures the water is safe for consumption and meets regulatory standards.

-

Chemical Manufacturing:

Accurate dosing of raw materials and additives is crucial in chemical production to maintain product quality and consistency.

-

Pharmaceuticals:

In the pharmaceutical industry, dosing pumps are used to dispense precise amounts of ingredients in the production of medications, ensuring dosage accuracy and efficacy.

-

Food and Beverage:

Dosing pumps help in the accurate addition of flavors, colorants, and preservatives, maintaining the quality and taste of food and beverages.

Conclusion

Dosing pumps play a vital role in ensuring precision and accuracy in industrial processes. Through their sophisticated design and advanced control systems, they deliver exact amounts of fluids consistently, maintaining the integrity of operations across various industries. As technology continues to advance, we can expect dosing pumps to become even more efficient and reliable, further enhancing their contribution to industrial precision.

Understanding the science behind dosing pumps not only highlights their importance but also underscores the meticulous engineering that goes into their design. For industries that rely on precise fluid management, dosing pumps are an indispensable tool, ensuring efficiency, quality, and safety in every application.