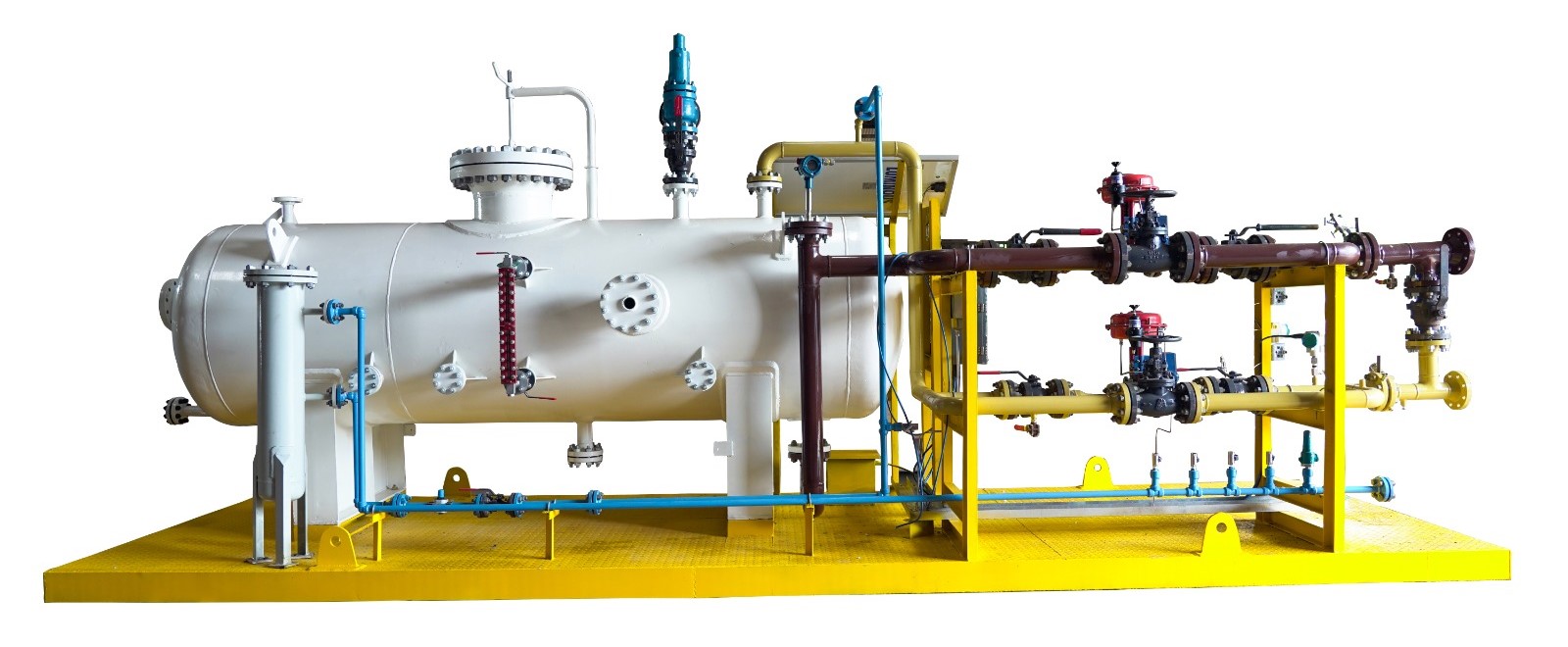

Oil and Gas Separator

An Oil and Gas Separator is a crucial pressure vessel designed for separating the components of a well stream, which typically consists of gas, oil, and water. These separators are employed in both onshore processing facilities and offshore platforms to ensure the efficient separation of fluids extracted from oil and gas wells. Based on the configuration and design, Oil and Gas Separators can be categorized into different types, each serving specific operational requirements.

Separator Configurations

Horizontal Separator

A separator where the vessel is oriented horizontally, providing an elongated chamber for separating fluids, ideal for handling larger volumes of fluids with a clear separation.

Vertical Separator

A vertically oriented separator, often used in compact or space-constrained areas. These are effective in separating gases and liquids, particularly in applications with lower flow rates.

Spherical Separator

A spherical-shaped separator, providing a compact and efficient design. It is typically used when space and weight are critical factors, such as on offshore platforms.

Separation Functions

Primary Phase Separator :

- Used in the initial stage of separation, it handles the bulk separation of gas and liquids from the well stream.

Test Separator :

- Primarily used for testing purposes, these separators help assess the properties of the well stream, such as flow rates and compositions, to optimize production.

High-Pressure Separator :

- Designed to operate under high-pressure conditions, these separators are crucial in initial separation stages where pressure is typically higher.

Low-Pressure Separator :

- Operates at lower pressures, usually following a high-pressure separator, to refine the separation process.

Gas Scrubber :

- A specialized separator that focuses on removing solid particles and liquid droplets from gas streams, ensuring that the gas sent to further processing is clean and free from contaminants.

Degasser :

- A type of separator used specifically to remove dissolved gases from liquids, particularly in scenarios where gas needs to be separated from oil or water for proper handling and transport.

To fulfill operational demands, oil and gas separators are commonly designed in several stages. The initial stage separator serves for preliminary separation of the phases, while the subsequent stages—second and third—are used for further purification of each phase, including gas, oil, and water. Depending on the application, these separators may also be known as deliquilizers or degassers. Deliquilizers are specialized in removing liquid droplets from a gas stream, whereas degassers are designed to eliminate dissolved gas bubbles from a liquid stream.

© 2026 NND Oil & Gas All Rights Reserved. | Privacy Policy | Terms & Conditions | Cookie Policy | Sitemap

- Designed & Maintained By Equos Infotech Pvt Ltd