Why Inline Static Mixers Are Revolutionizing Fluid Mixing in Industrial Applications

Introduction

Efficient mixing is a cornerstone of many industrial processes, from chemical manufacturing to oil and gas production. Among the best solutions available today are inline static mixers —devices that provide consistent, high-quality mixing without moving parts. Their growing popularity comes from their simplicity, durability, and cost-effectiveness.

1.What Is an Inline Static Mixer?

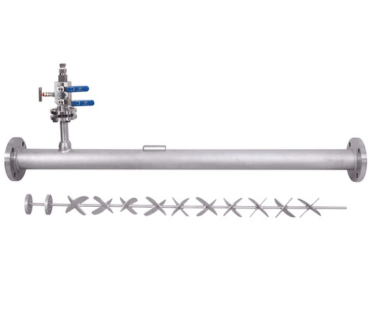

An inline static mixer is installed directly inside a pipeline, featuring fixed internal elements that create turbulence and split the flow as fluids pass through. This ensures rapid and uniform mixing of liquids, gases, or slurries without the need for mechanical agitation.

Unlike traditional mixers, static mixers don’t require motors or power inputs, making them ideal for continuous flow operations where maintenance and downtime need to be minimized.

Key Advantages of Inline Static Mixers:

-

Low Maintenance: No moving parts means fewer failures and less upkeep.

-

Energy Savings: Uses the existing flow energy, no extra power needed.

-

Compact Design: Fits easily into existing pipework with minimal space requirements.

-

Versatile Applications: Works with liquids, gases, and multiphase flows.

-

Scalable: From small lab systems to large industrial pipelines.

2.Why Choose Inline Static Mixers for Your Operation?

With their robust design and efficient mixing capabilities, Inline static mixers reduce operational costs and improve product quality. Their simplicity translates to fewer failures and longer service life, making them a smart investment for any process involving fluid blending.

Common Uses in Industry:

-

Chemical Processing : Mixing reactants for efficient reactions.

-

Water Treatment : Even distribution of chemicals like chlorine.

-

Compact Design: Fits easily into existing pipework with minimal space requirements.

-

Food & Beverage : Blending ingredients without contamination.

-

Oil & Gas : Homogenizing fuel additives and blending crude oil.

Conclusion

Inline static mixers offer a powerful, maintenance-free solution for efficient fluid mixing across a wide range of industries. Their compact design, energy efficiency, and consistent performance make them ideal for applications in oil & gas, water treatment, chemical processing, and more. Whether you’re looking to reduce costs or improve product quality, inline static mixers are a smart, long-term investment for streamlined operations.