Understanding Corrosion Coupons and Their Role in Industrial Applications

What Are Corrosion Coupons?

Corrosion coupons are standardized metal samples placed in systems to measure rates of corrosion. Typically made from the same material as monitored equipment, they provide precise insights into corrosion processes.

How Corrosion Coupons Work

- 1. Preparation :

Coupons undergo meticulous cleaning and recording of initial weights and dimensions to ensure accurate results. - 2. Exposure :

Positioned in environments requiring corrosion monitoring, such as pipelines or cooling towers. - 3. Retrieval and Analysis:

After a defined period, coupons are retrieved, cleaned of corrosion products, re-weighed, and the weight loss calculated to determine corrosion rates. - 4. Reporting: :

Data is compiled into reports aiding understanding of system corrosion dynamics for informed maintenance and mitigation decisions.

Applications of Corrosion Coupons

- 1. Oil and Gas Industry :

Vital for monitoring internal corrosion in pipelines and storage infrastructure, ensuring safe hydrocarbon transportation. - 2. Water Treatment Plants :

Crucial in monitoring water quality effects on metallic components, ensuring equipment longevity and safe drinking water. - 3. Manufacturing :

Manufacturer coupons play a key role in assessing corrosiveness in chemical processing, guiding material and coating selections for prolonged equipment life. - 4. Power Generation :

Essential for monitoring boiler, turbine, and critical component conditions in various power plant types, ensuring continuous and efficient energy production. - 4. Marine Industry :

Monitors and manages corrosion in harsh marine environments, ensuring marine vessel and offshore platform safety and durability.

Types of Corrosion Coupons

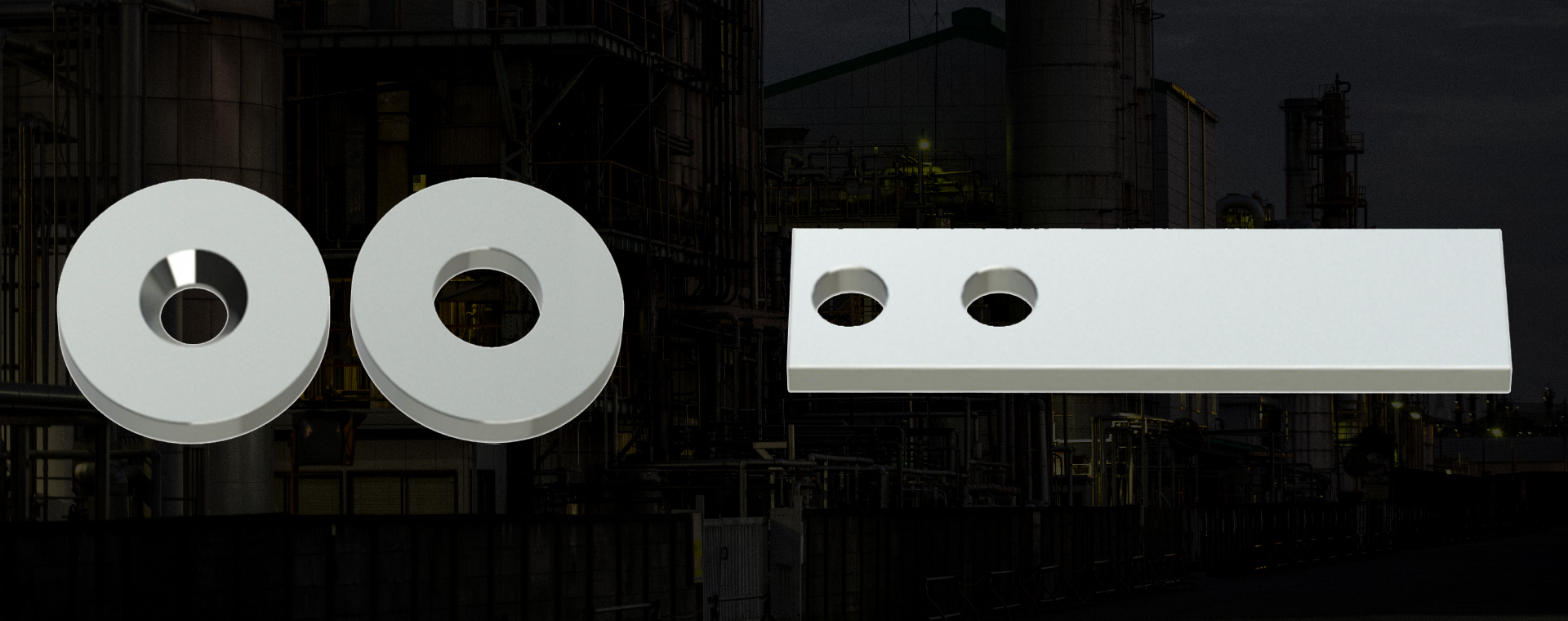

- 1. Flat Coupons :

Standard pieces used for easy insertion and removal from systems. - 2. Disc Coupons :

Circular coupons suited for high-pressure systems with limited space. - 3. Strip Coupons :

Thin, elongated coupons for monitoring corrosion over larger surface areas. - 4. Specialty Coupons :

Custom-designed to mimic specific system components or conditions for precise data collection.

Best Practices for Using Corrosion Coupons

- 1. Proper Preparation :

Ensures coupons are contamination-free for accurate results. - 2. Strategic Placement :

Positions coupons in representative locations for precise corrosion rate data. - 3. Regular Monitoring :

Consistent retrieval and analysis for tracking corrosion rate changes over time.

- 4. Expert Data Interpretation :

Collaborates with corrosion experts for informed maintenance and control strategy decisions. - 5. Thorough Documentation :

Detailed records of all corrosion monitoring activities ensure comprehensive system oversight.

Case Study: Manufacturing Industry

Consider a manufacturing plant producing chemicals. Facing rising maintenance costs from corroded equipment, the plant implemented a corrosion monitoring program using manufacturer coupons:

- Coupon Selection : Opted for flat coupons matching their tanks and pipelines materials.

- Strategic Placement : Positioned coupons in suspected high corrosion areas.

- Results : Witnessed decreased maintenance costs and prolonged equipment lifespan due to reduced corrosion rates.

- Monitoring : Regular analysis revealed areas with elevated corrosion rates, prompting adjustments in chemical treatments and protective measures.

Conclusion

Corrosion presents significant challenges across industries, necessitating effective monitoring and management strategies like corrosion coupons . Their role in enhancing operational efficiency, ensuring safety, and meeting regulatory requirements makes them indispensable in safeguarding industrial assets. By leveraging corrosion coupons effectively, industries can mitigate risks, optimize processes, and secure long-term success amidst evolving challenges.